Advantages

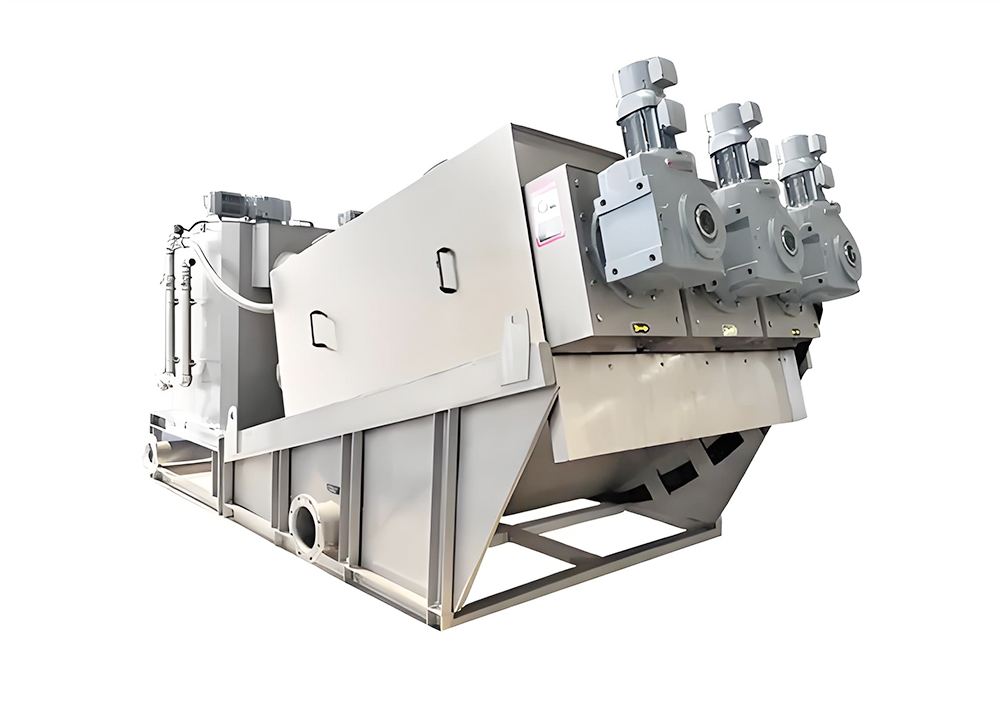

The

Screw Press Sludge Dewatering Machine HBD-202 offers several notable advantages. Firstly, it ensures excellent large-scale dewatering efficiency. Engineered for substantial sludge treatment demands, it effectively reduces sludge moisture content for large volumes, enhancing productivity in

Wastewater Management. Secondly, it boasts easy operation and low maintenance. The integrated structure and reliable components simplify operation, while its durable design minimizes maintenance frequency and costs. Moreover, it features stable and robust performance. Constructed with high-quality materials and a reinforced screw mechanism, it operates steadily with minimal downtime, ensuring continuous sludge treatment. Additionally, it enables versatile sludge adaptation. Capable of handling various sludge types from municipal, industrial, and commercial sources, it meets diverse dewatering requirements.

Detailed Features

In terms of detailed features, this machine has a precision-engineered screw press structure optimized for large-scale dewatering. It integrates a sludge feeding unit, multi-stage screw pressing module, and discharge system, working synergistically to reduce sludge moisture content. The machine is equipped with a heavy-duty screw shaft, wear-resistant filter elements, and intelligent control components to ensure thorough and efficient sludge dewatering. Accessible inspection ports and modular components facilitate easy maintenance and routine checks. Built with corrosion-resistant materials, it withstands the harsh conditions of sludge treatment environments. The HBD-202 model designation signifies its specialization in large-capacity screw press sludge dewatering, complying with strict industry standards for efficiency, reliability, and functionality, making it a dependable solution for

Sludge Management.

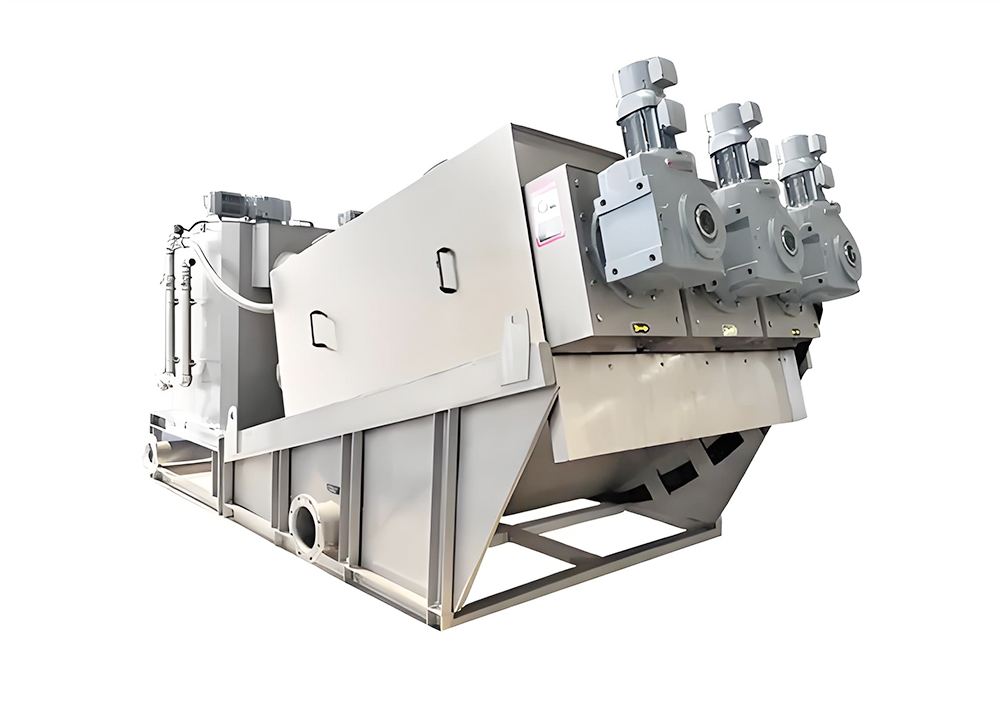

Application Range

The application range of the Screw Press Sludge Dewatering Machine HBD-202 is concentrated in the wastewater treatment, environmental protection, and industrial sectors, specifically for sludge dewatering tasks in large-sized municipal sewage plants, industrial complexes, and commercial wastewater management systems with substantial sludge volumes. It is suitable for use in large water treatment plants, manufacturing units, and other industries where efficient large-capacity sludge dewatering is a priority. In large-scale wastewater treatment facilities and industrial sites, it serves as a practical and reliable choice that balances dewatering efficiency and operational scalability. It is also relevant for environmental engineering companies and facility managers aiming to implement effective sludge management for large-scale operations, replacing traditional dewatering methods to optimize workflow and operational efficiency. Whether in a large municipal sewage plant or an industrial complex with substantial sludge generation, this machine meets the demanding needs of sludge dewatering with its efficient design and reliable performance.